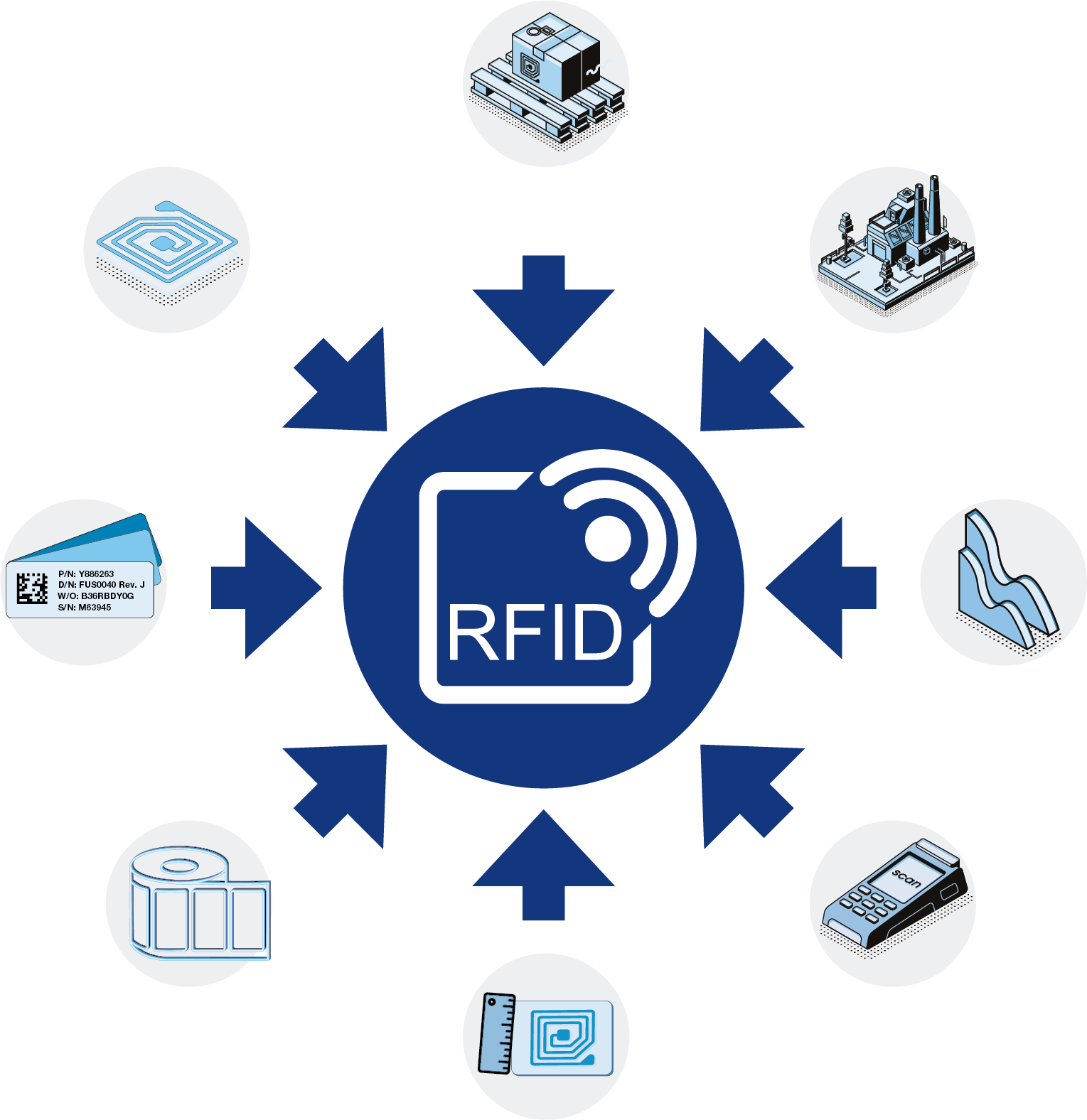

Faster maintenance with RFID labels & handheld scanners

RFID labels can provide any wagon or part with a unique, standardised identifier

that can be read reliably from a distance with a UHF RFID scanner, or up close with

a recent, NFC-enabled smartphone. The identifier can be linked to a company ERPsystem

via an Asset Management software. This will enable maintenance teams to

access quickly any item’s maintenance history, mileage, technical documentation,

re-order code and any information they need to deliver their best work fast.

Proximity alerts can be provided via the software to locate parts even faster.

Errors related to manually copying serial numbers or other identifiers can be

avoided. Relevant documentation can become available immediately on handheld

scanners, and interventions can be added easily to the asset’s maintenance history.

Similar assets with the same make and model, or produced in the same lot, can be

highlighted quickly for predictive maintenance. Steps on how to solve the problem

can become accessible for other maintenance teams so they can intervene even

faster.

Print and program RFID labels at your premises

RFID labels can still include a human readable, and a datamatrix code. Printers are

available that can print-and-program UHF RFID labels or HF NFC RFID labels in one

go at any location.